As per any tiny space, you will need some type of multifunctional furniture in your new home. Our most complex task was designing a couch that could also be a full size bed and still have ample drawer storage underneath.

This was the first piece of furniture were build because we know the van would have to morph around the space that this took up. The first problem to solve was how to get the bed to go from a couch to a full size bed. We knew we need some type of bed hinge like one you would find on a futon. So we went to an RV junkyard and found a “rock and roll” bed hinge similar to this product. (https://amzn.to/2SEZz0L)

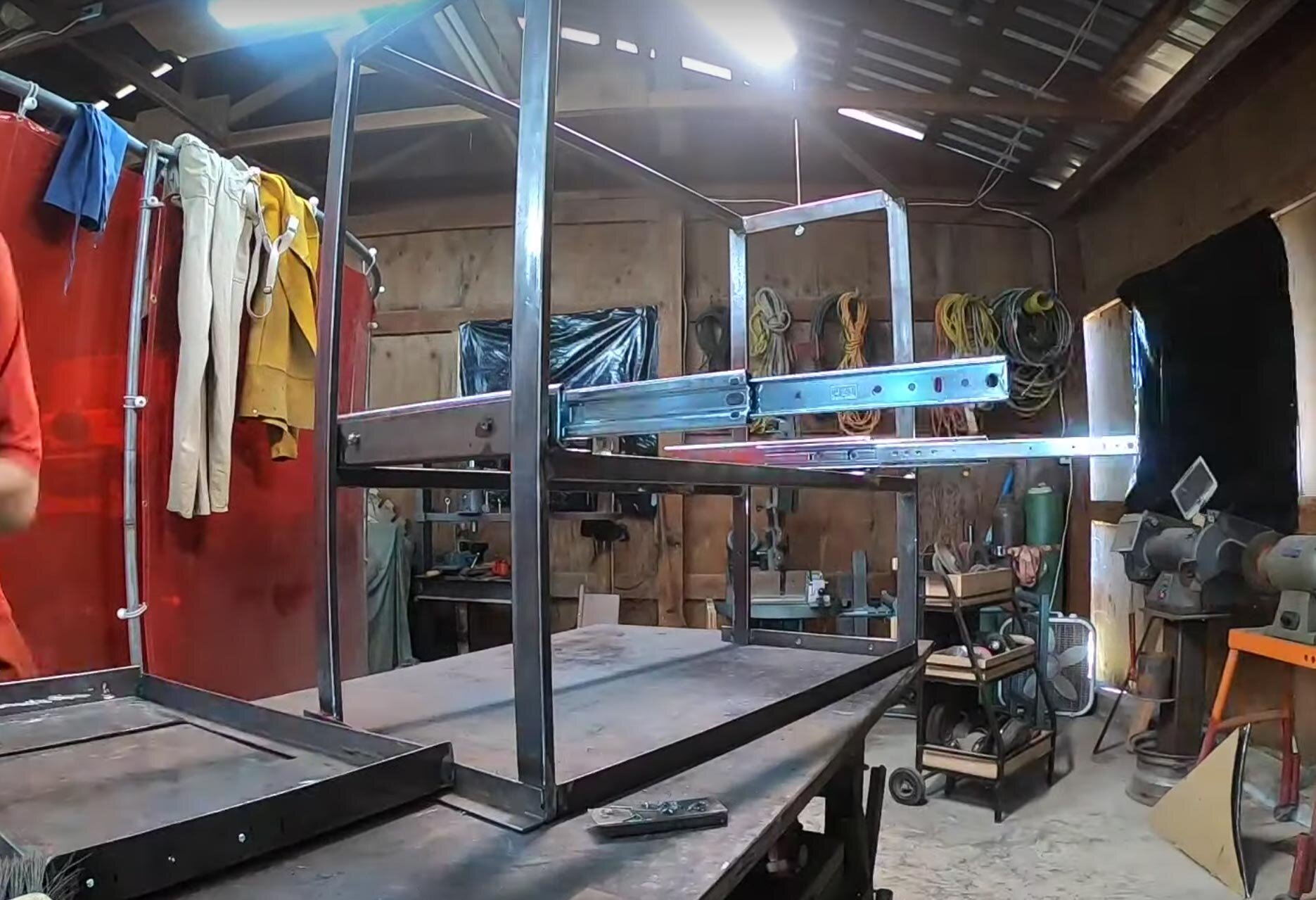

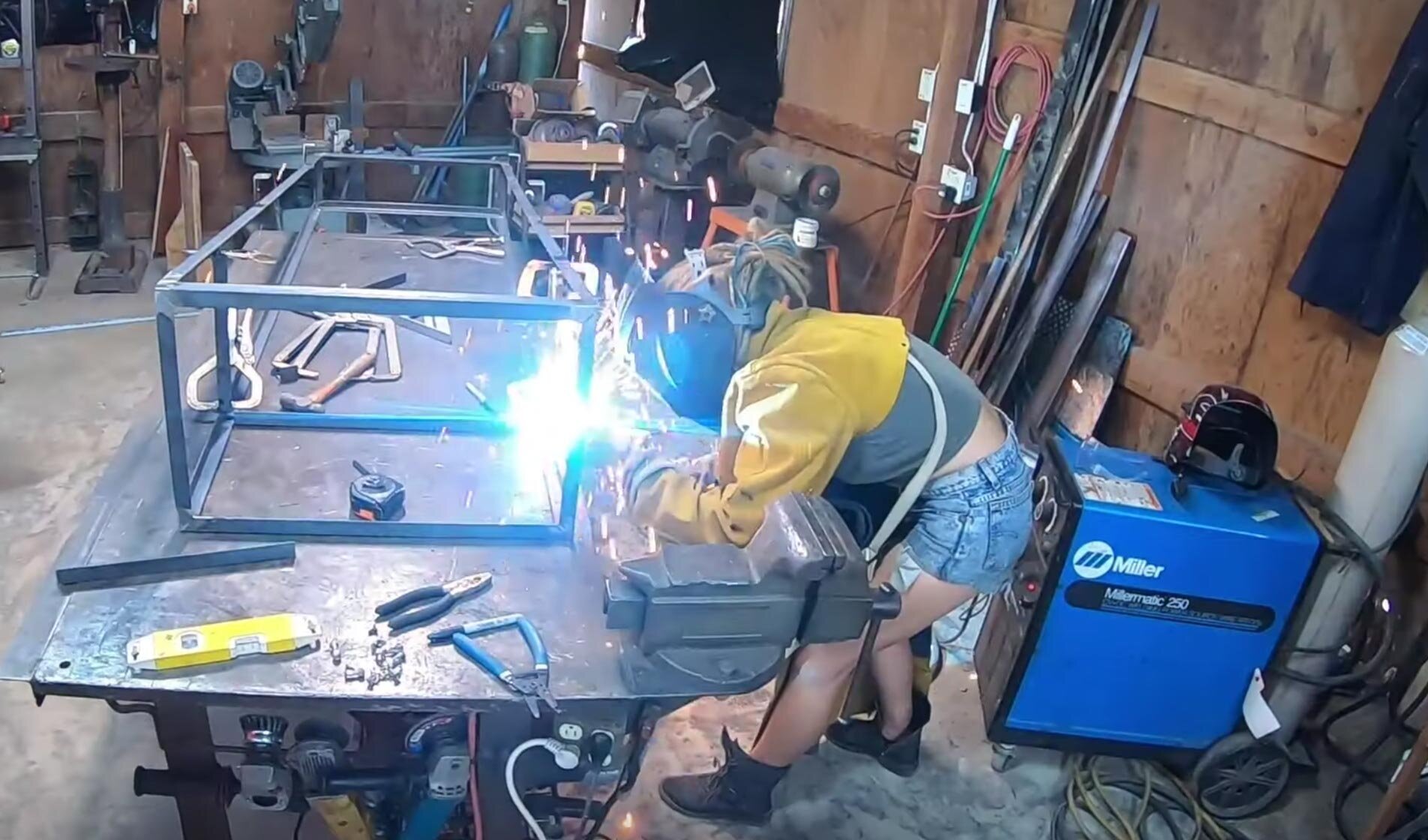

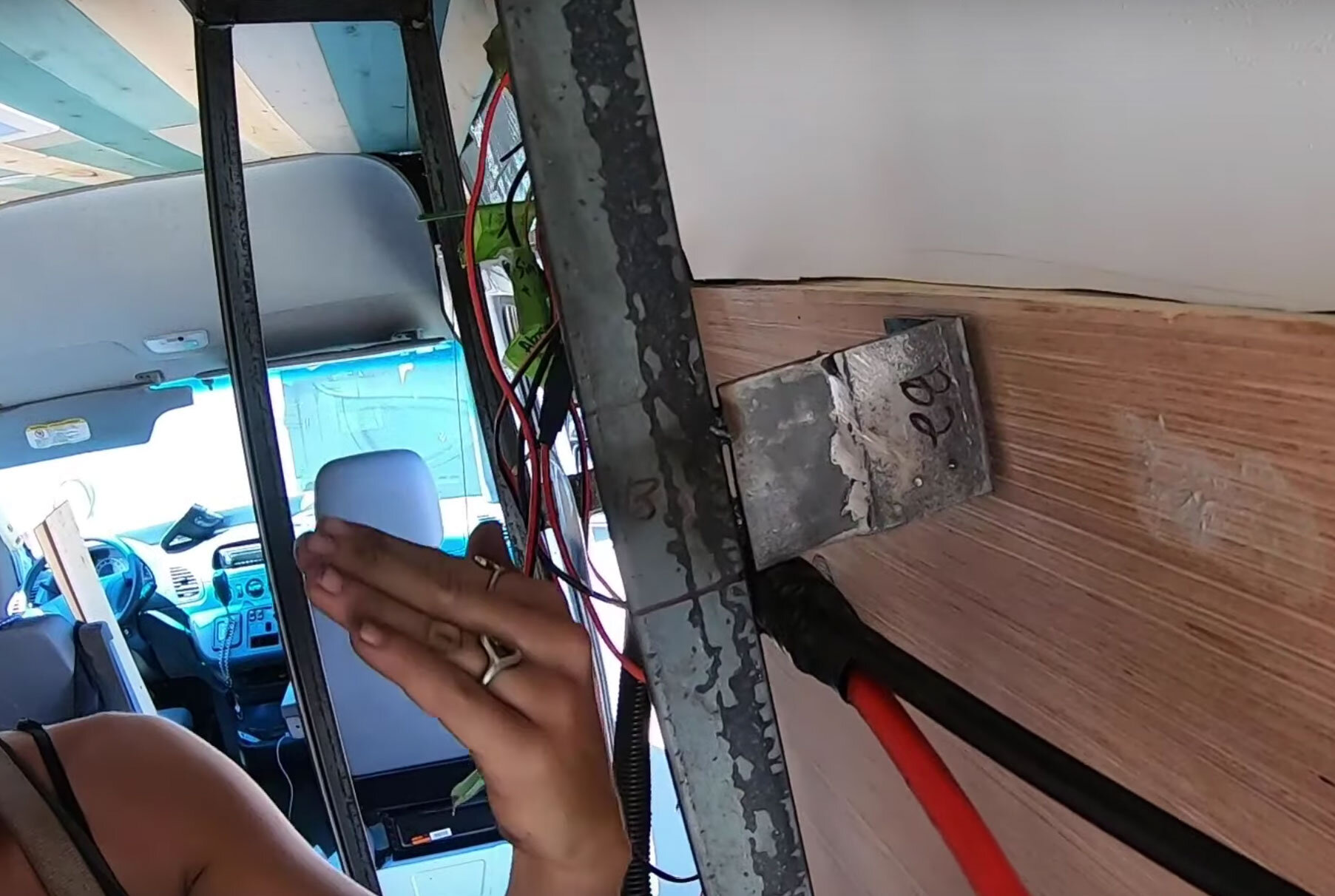

After finding the proper hinge, we welded the base and legs of the bed. The hinges were then bolted onto the edge of the frame and tested multiple times. Once we realized that it was going to work, we needed to design a way that the couch/bed could pull out to accommodate the full size mattress, when it goes into “bed mode”. What we needed was over a foot of additional support for under the mattress, once it was converted into “bed mode”. We designed a pull out frame under the couch frame that you could pull out to get the additional support you needed.

Now, we needed a frame to hold it all together. We were able to use 3/4” plywood and cut it to size of the bed frame with an additional piece that would be piano hinged to the base. So that way, it could support the mattress on the additional pull out slats we added. (See Photos)

Once the bed frame was in and working, we needed to get a mattress on the bed to see how easy it was to use this design. We found the perfect mattress at IKEA and after some alterations it fit perfectly to our bed frame. After some trial and error and many alterations on the sewing machine, we got the mattress to fit perfectly and is very comfortable in both “couch mode” and “bed mode”.

We successfully designed a functional couch/bed and now we needed to add storage underneath the frame. We installed two heavy duty drawers frames and built out two large and deep drawers, out of a nice refinished birch to give it a professional look. We also use the bed to store our 26 gallon fresh water tank underneath. We were extremely pleased with how this multifunctional bed turned out and that most of all it was both comfortable and functional.